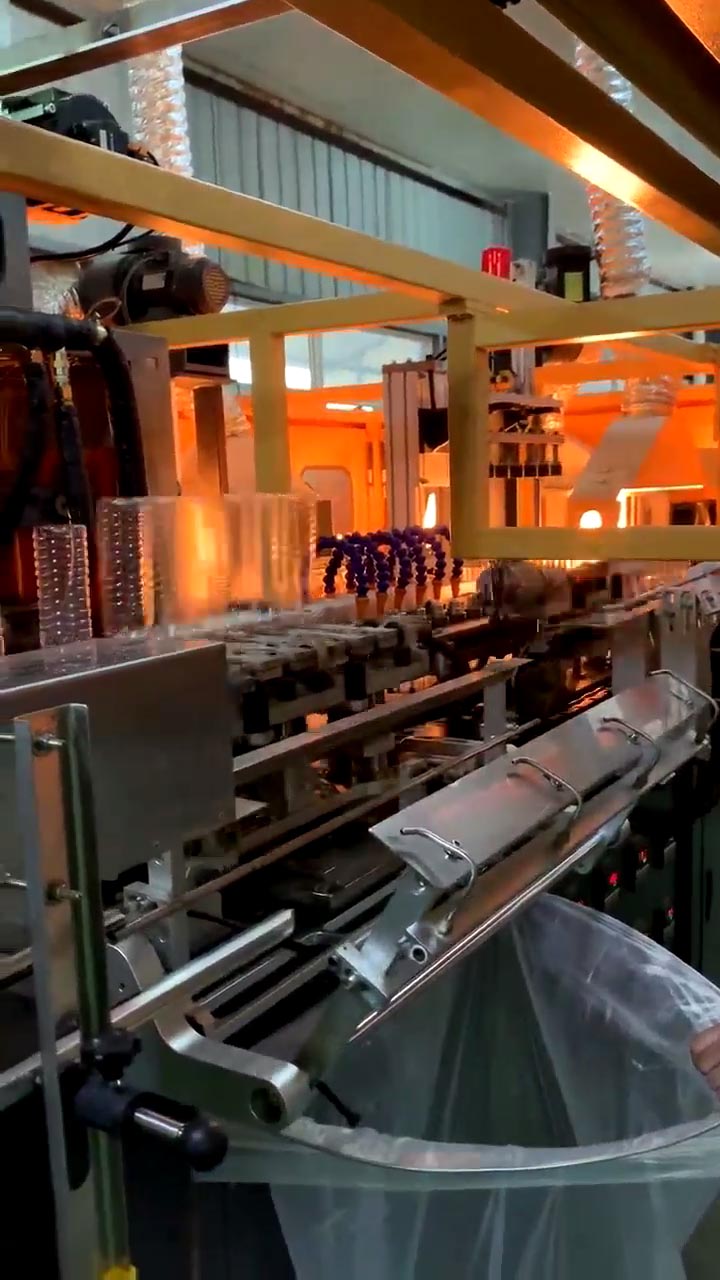

6 Cavities fully automatic blow molding making machines maximum 2 Liter

6 Cavities fully automatic blow molding making machines maximum 2 Liter

2024/3/28 , visitsa stable two-step blow-down stretch automatic blowing machine. It can be used from 4 cavity to 12 cavity with a speed of 2000 bottles per hour (750 ml plastic bottles), max volume 2L plastic bottle, suitable for blowing any kind of carbonated beverage bottle, sparkling beverage bottle,pure water bottle, mineral water bottle, fruit juice beverage bottle, cosmetic bottles, large diameter bottles, high temperature resistance bottles and other packaging bottles.

6 Cavity Full Automatic Blow Moulding Machine, with production capacity at 6,000~7,000 bottles per hour, is suitable for large water production line. The PLC micro-computer controller and human machine interface create simple operation. Independent operation station, far from heating area, is more flexible, safe to arrange operating positions.

√√ Brand: Meto Machinery-----Automatic Blowing Machine

√√ Application:0.2-2L

√√ Capacity:6000BPH-7000BPH

| Item |

MT-6 | |

| Bottle type specification | Cavity | 6 |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 28-30mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Capacity specification | Theory output | 12000-14000 bph |

| Bottle type volume | 500ml | |

| Bottle type weight | 17g | |

| Bottle type | Round | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 2KW/3KW | |

| Maximum heating power | 76KW | |

| All electric machine installation | 98KW | |

| Actual consumption | 30%-60% | |

| Air pressure specification | Work pressure | 5-6kg/c㎡ |

| Blow bottle pressure | 25-45kg/c㎡ | |

| Higher -pressure gas consumption | 8000Ltr/min | |

| Forzen water specification | Work pressure | 5-6 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 120L/min | |

| Machine specification | Machine size | 5.2x2.1x2.38 |

| Machine weight | 8.5ton | |

Bottle blowing machine video

-

Ruby

Ruby  +86 13757660057

+86 13757660057 meto@kemomachine.com

meto@kemomachine.com +86 13757660057

+86 13757660057 aaa

aaa Scan, Add Friends

Scan, Add Friends

Helpline and Support

008613757660057

Get A Free Consultation